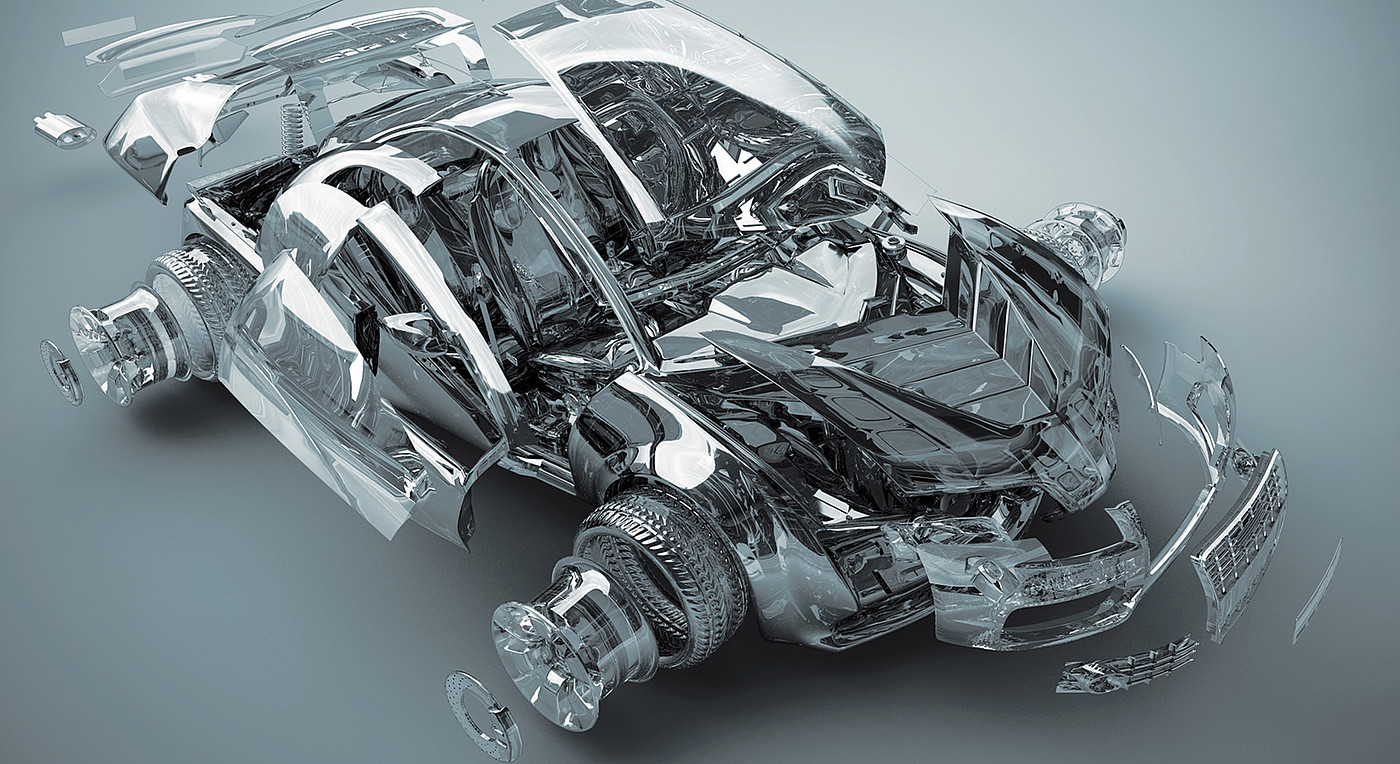

With our extensive engineering expertise, we take over responsibility for developing modules. We integrate components and systems functionally and set ourselves the challenge of increasing quality demands. From preliminary development and series development to series support after the start of production of individual parts, modules and the development of complete vehicles, we combine expert knowledge with the latest lightweight construction material technology trends.

In a network of OEM, CAx experts and components/module suppliers, we ensure that technical , economic and procedural goals are attained.

Function fulfilment and cost efficiency are the challenge, lightweight construction and hybrid technologies are our tools.

We take responsibility for the development of complete bodies and act as a system integrator at all relevant interfaces.

Our goal: production-optimised development with optimum product features at minimum cost and weight.

Perceived value and quality play a significant role. The balance between optics, texture, usability, function and cost is the main theme of the development of the interior.

Included in the early project phase of concept selection and material definition, we work to achieve an optimum in goal conflict with regard to quality and cost.

Nowadays, a good seat is no longer only characterized by the ergonomics and driving safety.

The quality of the seat also has to be right, and this can often only be assessed while driving.

In addition to the know-how of various suitable materials such as foams, covers, linings and much more, the EDAG competence team offers besides CAE calculation also testing of the manufacturability of individual features as well as feasibility tests in its own accredited test centers.

The understanding of emotional design as well as the development expertise of adaptive systems in the vehicle exterior allow us to implement an OEM-brand DNA.

The external appearance of the vehicle must be in line with the signature values of the brand. The same also applies to the development of the add-on parts. Whether it's spoilers, panels, windows, glass roof systems or complete modules, e.g. bumper systems – we are the engineering specialists for add-on parts.

The range of this module scope stretches from the development of glazing through to the optimum design of the lighting.

No component makes a more marked contribution to the appearance of a car than its lights. They give a vehicle character and its own unique expression. Whether they are refined, grand, friendly or even aggressive - the lights are the "eyes" of a car, and are optimised to give the desired effect.

New technologies with drive types present new challenges. Our expertise in overall vehicle development qualifies us as a partner in the integration of electric, hybrid, fuel cell and conventional drives in your platforms.

The future of the car is determined by different drive concepts. The key to success lies in intelligent integration in existing architectures.

Our drive experts handle this for you.

We accompany you through the transformation from mechanical to mechatronic chassis systems and focus on new technologies for the chassis of the future.

The chassis of the future will increasingly be more intelligent and more efficient and therefore an important component of the strategy for reducing CO2. We support you in developing new technologies that master the requirements of autonomous driving and progress networking.