Lightweight design is a key success factor when it comes to CO2 savings in mobility. It is therefore vital that sustainability aspects of lightweight vehicle components can already be measured and optimized during the development process.

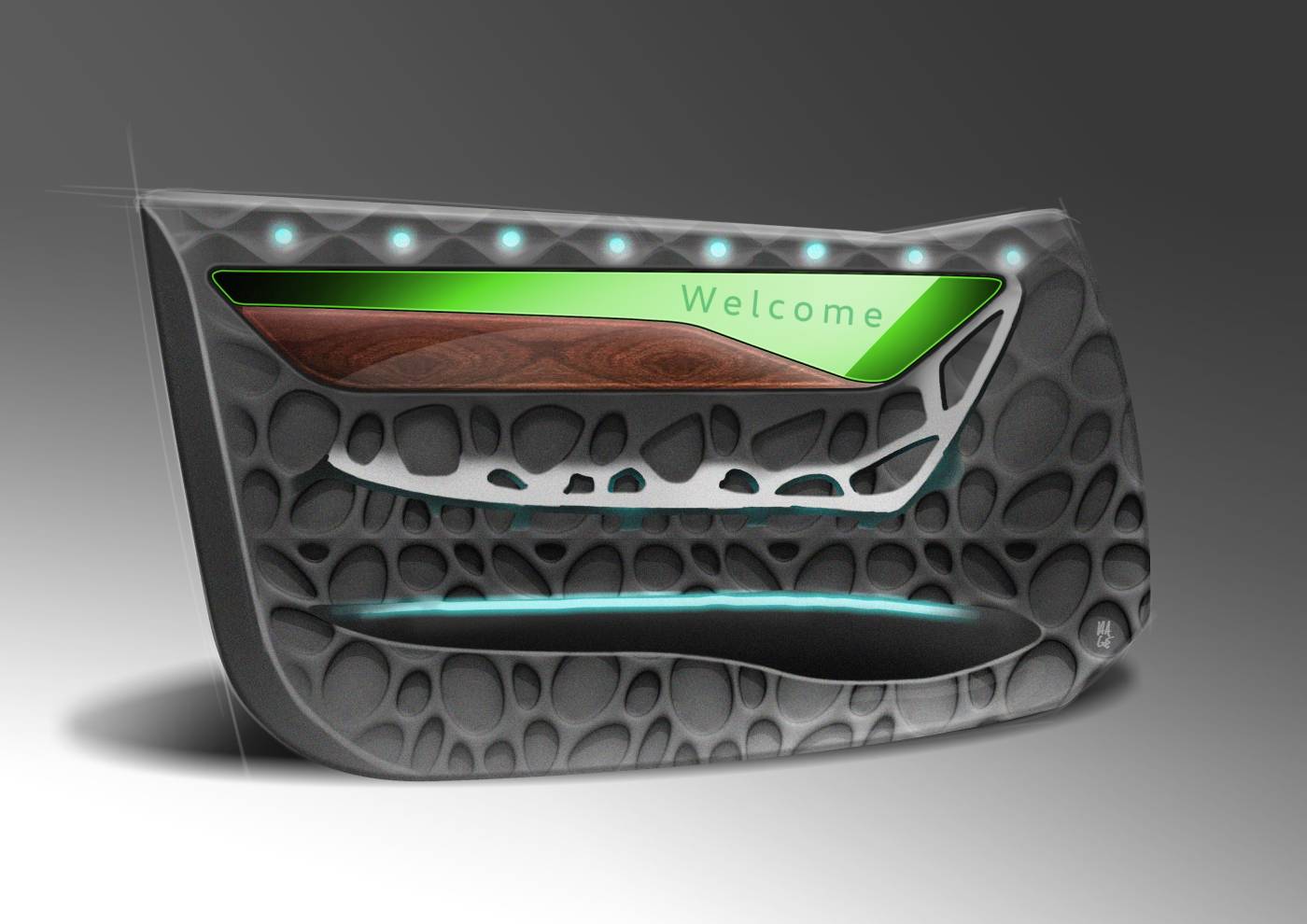

To this end, LCA methods are integrated into the software tools used for development, for instance CAD programs (Catia, NX, etc.), and FE simulation programs. In addition, AI and bionic algorithms are being developed to enable more sustainable components to be developed more rapidly.

The designs created with the help of AI and bionics are evaluated for sustainability using the LCA methods implemented, and subsequently optimized for sustainability by means of automated development loops within the ELISE software.

What this might look like in practice is what we are working on in the research project "Bionics and AI for sustainable integration in product development for resource-efficient lightweight construction" (BIKINI), along with the University of Paderborn, Additive Marking GmbH, Atos Deutschland, Krause DiMaTec GmbH, RHaug GmbH, and the Alfred Wegener Institute. The BIKINI project is being funded by the Federal Ministry for Economic Affairs & Energy (BMWi).

Similar projects:

VariKa: Consistently networked product and production engineering for scalable lightweight solutions

FlexHyJoin: New hybrid joining process for lightweight design suitable for mass production