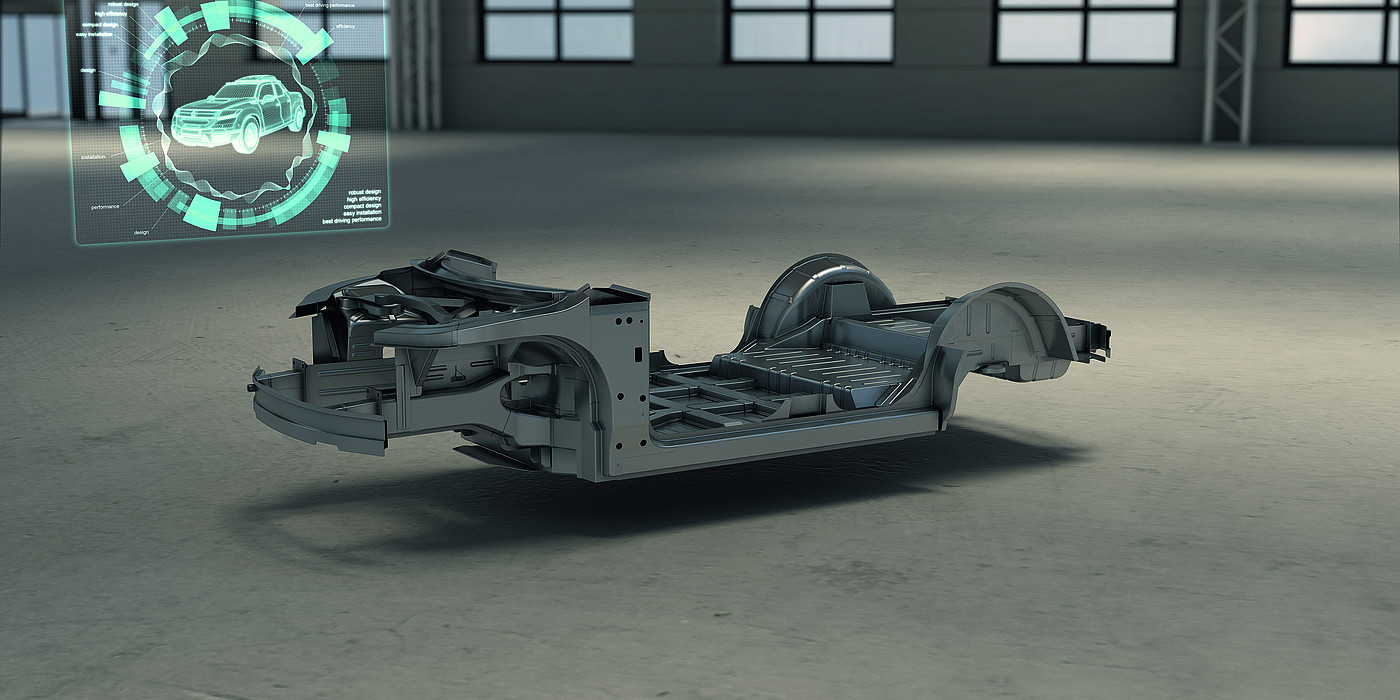

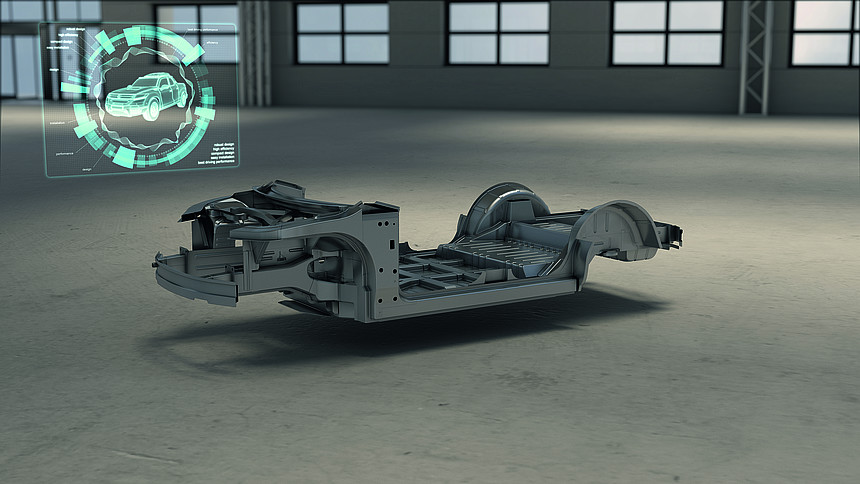

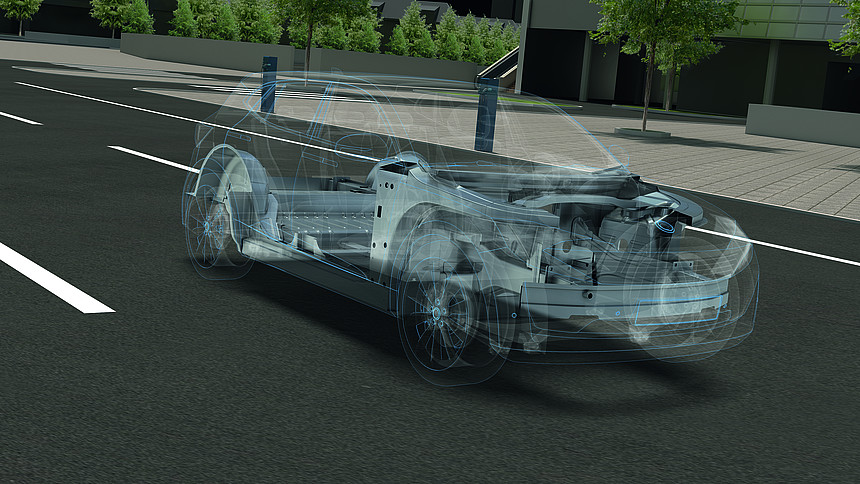

The only thing that is predefined in the SCALEbase is the distance between the front wheel and the heel point. All other measures of length and width can be varied, as its steel structure makes extensive use of sections. This makes it possible for the electric vehicle floor assembly to be scaled to fit just about any mid-range and luxury class eCar. The ideal basis for manufacturers' platform solutions.

At the same time, local concept, dimensioning, design and factory planning requirements imposed on the vehicle by the automotive companies can also be taken into account. With this advisory concept, the data basis and corresponding team of experts, it is possible for manufacturers to cut at least three to four months off the development period and significantly reduce their budget. In this way, the EDAG Group – the world's largest independent engineering partner to the automotive industry – offers its customers considerable advantages in the costly transition of the industry to electric mobility.

Another benefit: its scalability is not the only outstanding characteristic of SCALEbase; it is also ideal for the structural integration of battery systems. This means that the automotive companies can work with the EDAG Group experts to define and roughly design the various power levels of the planned eCar and battery module – depending on local preferences and the size of the vehicle.

To ensure that the electric vehicle floor assembly would be suitable for international use, current and future crash requirements from a large number of markets were taken into account during development. Should a crash occur, SCALEbase has optimised load paths to meet the ambitious requirements for the protection of passengers and the battery in the event of a side collision. "In projects where it has been used, the SCALEbase platform has already demonstrated the fact that it offers customers added value," explains Micheal Schäfer, technical project leader. "Immediately after the concept phase, development work was begun on a vehicle for a new manufacturer. This is evidence of the enormous potential of our system." A fundamental basis for the realisation of the eCar revolution.

About the EDAG Group

EDAG is an independent engineering service provider working for the global automotive industry. The company has a global network of some 60 branches at the world's major automobile centres to serve leading national and interna-tional vehicle manufacturers and technologically discerning automotive suppliers.

In addition, EDAG also offers engineering services in the vehicle engineering, electrics/electronics and production solutions segments. This extensive competence enables EDAG to provide its customers with all-round support, from the original idea to design, through to product development, prototype construction and even turn-key production systems. As an innovative technological leader, the company also has competence centres for ground-breaking fu-ture technologies for the automotive industry: lightweight design, eMobility, digitalisation, integral safety and new production technologies.

In 2018, the company achieved a sales volume of € 792 million and an adjusted EBIT of € 47.6 million. On 31st De-cember, 2018, EDAG employed a global workforce of 8,641 (including apprentices).

Do you have any questions, or need further information?

Christoph Horvath

Press Spokesman of EDAG

Tel.: +49 (0) 661- 6000 570

Mobile: +49 (0) 171- 8765 310 65205 Wiesbaden

E-mail: christoph.horvath@edag.com

Head office

EDAG Engineering GmbH

Kreuzberger Ring 40

65205 Wiesbaden

www.edag.com